Imagine developing a three-dimensional object on a flat computer screen and then sending that image to a 3D printer that can instantly create the object by making many passes over a material that was inserted in the printer.

Well the machines are here, and the process is called 3D printing.

Technology is always being enhanced, and people everywhere are always trying to do things more efficiently. Social media, the iPhone, the iPod, cars that park themselves and the Dyson Ball vacuum are just a few of the latest advancements in technology.

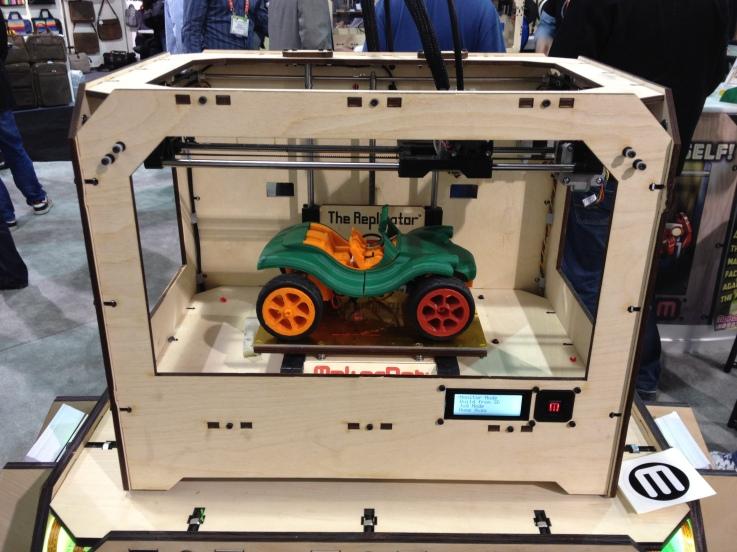

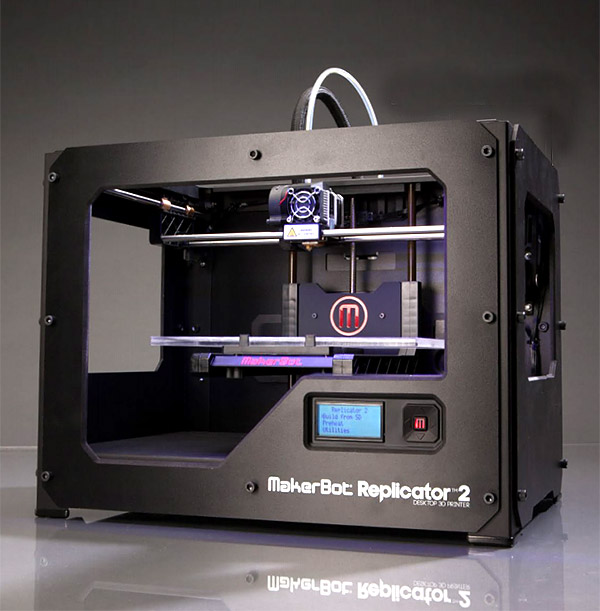

A source for the design was recently featured in Wired magazine. The October 2012 issue talks about the machine that will change the world. This machine is the new Replicator 3D Printer, which allows you to print objects in your own home.

The 3D printing technique, selective laser sintering, directs a powerful laser at a thin layer of powdered medium – typically plastic, metal, ceramic, or glass – that’s spread in a thin layer on a flat bed. The heat from the laser melts the medium in a precise pattern that is controlled by the computer-aided design (CAD) system and represents a cross-section of the item to be manufactured; the bed is then lowered and the process repeated. 3D printing or modeling is used largely by designers, engineers and hobbyists for concept development and product design. 3D printers can create items using rubber materials, hard plastic, polyurethane-like materials, temperature-resistant materials and opaque and transparent materials.

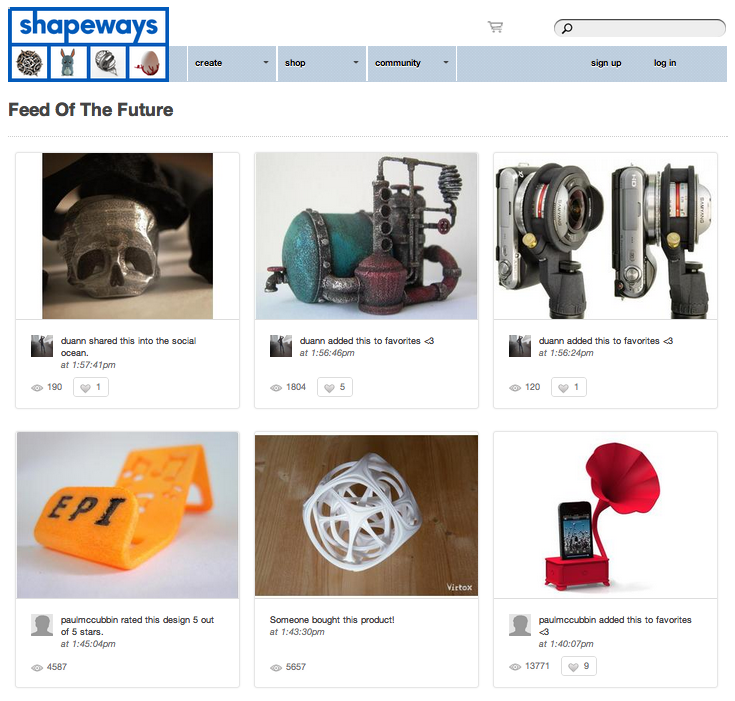

According to Bloomberg Businessweek under Technology, an unusual type of store has opened up on 298 Mulberry Street in Manhattan and is the first store to sell the MakerBot products. MakerBot is the leading consumer 3D print company. MakerBot products before being available in this Manhattan store were not thinking of going the retail route. In the beginning you could only buy MakerBot products from a company called Shapeways from their online website. The message of Shapeways is that this company is always trying to build a product that will solve a problem or meet our needs.

The place where MakerBot creates their products is a place called the BotCave. From several investors such as Jeff Bezos who is the founder of Amazon, MakerBot last year raised $10 million to help fund their company’s expansion. The 3D printer being talked about in the Wired Magazine article is called The Replicator and it sells for the same price as The Cub from 3D systems at $1,299. The entry level Replicator 2 is priced at $2,199 and can generate objects up to 11 by 6 inches in ecofriendly material.

Shapeways is another company that has started creating their own 3D printers. On www.shapeways.com, you can see the many photos of things people have created and get your own ideas of what you can create. The prices of what people are charging for what they have created are also listed next to their item as well. You will see on the Shapeways website all the amazing inventions that with 3D printing your mind can develop.

Another player in the in 3D printer arena is the company 3D Systems. You can check out all their models at www.3dsystems.com and to find out more information. There are 4 different 3D personal printer models that 3D Systems sells and they are the BotMill, RapMan & 3D Touch, ProJet 1500 and the Cube 3D Printer. Under BotMill the Axis 3D printer kit is the lowest priced 3D printer on the market at $999 and under RapMan & 3D Touch the most expensive model on the market will cost you $4,370 because it uses triple heads.

Whichever model one looks into, 3D printing is a big step for design firms, doctors, scientists, engineers and others who work with physical objects who have long tapped into the 3D printing technology – also known as ‘additive manufacturing’ – to build physical objects using blueprints produced by a 3D design program. A three-dimensional object is modeled by a designer using software such as CAD. 3D printing has become a favored way of prototyping new products without going to the expense of setting up full manufacturing lines.