‘At War With No Ammo’

As health officials scramble, residents band together to make masks to fight the COVID-19 war

Alliyah Steele knew she had to do something. She had seen far too many people living in a panic, worrying about how they would protect themselves and their families. She was determined to make her free time essential.

She began making masks.

With over 500,000 people infected and over 20,000 dead so far in the U.S. alone, coronavirus (COVID-19) is not expected to take its leave soon. Just as toilet paper sales have soared to new heights, shortages of masks, gloves, hand sanitizer, and antibacterial products have become widespread.

So Steele, who is a 16-year-old junior at Putnam Valley High School, helped the only way she knew how.

“It’s just so heartbreaking, People having to cut trash bags and wrap them around their faces and their scrubs or having to reuse these masks over days and days and days. I just want people to realize just how dire the situation is and that they really need help and that what we’re doing is important.”

Masks are important for preventing the inhalation from the air and exhalation into the air if one will be in otherwise normal proximity of a person who is infected and/or is infected with the virus themselves.

In no time, masks have become entirely unobtainable, yet they’ve remained crucial for all people to have access to. This has made situations difficult for healthcare facilities that have been filled to the brim with patients constantly.

“We are at war with no ammo,” as a surgeon from Fresno, California described it.

Steele is a national program co-director for ThinkSTEAM 4 Girls, co-president of her school’s Make a Difference Club, and she also has involvement with the Mercy College Center for STEM Education. In response to the high demand for personal protective medical equipment in hospitals and healthcare facilities, Steele created an initiative.

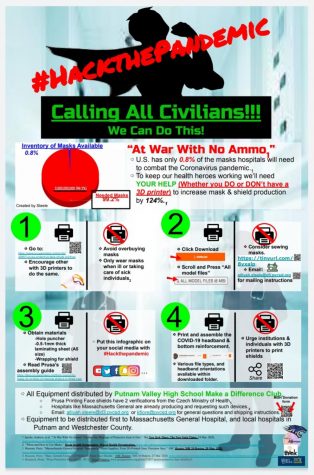

Her first order of business was to recruit civilians that might roll up their sleeves and either sew or 3D-print face masks and shields. She sent out a flyer, including step-by-step instructions for printing and sewing them. It even lists contact and shipping information for when they are ready to donate. Steele has a 3D-printer of her own and has been spending the past few weeks pushing out as many masks and shields as she can.

Putnam Valley High School’s Make a Difference Club and tech department are working with Steele to, well, make a difference. After sending around her flyer and spreading the word on Westchester’s NEWS 12 on March 24, about 15 people reached out to her to lend a hand.

Massachusetts General Hospital was the first place to receive a mask and shield donation from Steele and her army. They sent 30 masks in the first batch and 40 in the second. Putnam and Westchester hospitals are next on the list to receive mask and shield donations.

The masks they’re making will be used not only for health/medical personnel, but for waiting room occupants, custodial staff, and other non-medical workers too.

“There are a lot of essential workers right now that need them, so I have about 10 ready for the post office workers and I think other essential workers such as grocery store staff and the sanitation department would also enjoy our masks and shields. It’s especially important now that there are CDC and governmental recommendations for all essential workers to wear masks.”

Printing a single 3D face mask or shield can take up to two hours. When the masks and shields are finished printing, they require minimal labor to complete their assembly process, and then they’re ready to go. There are a few different acceptable plastics that can be used for making them, but it’s best to use PETG pla. To better fit the masks to faces, hot water or blow dryers can heat and mold the plastic.

Sewing face masks doesn’t take as long as it does to print them and they can be made by hand or with a sewing machine. The best fabric to use for these masks is 100 percent cotton, as it is the most breathable material. Model files for 3D face masks and shields and sewing patterns for face masks can be downloaded for free through the links in Steele’s flyer. Some templates even allow for masks to be made with an empty space inside for medical professionals to insert a filter if they so choose.

Steele urges all participants in this project to wear gloves and masks while they sew or print. Although each one is washed and sanitized prior to use, she wants the utmost care to be taken while handling the masks and shields throughout all parts of the process. Some people even individually wrap each one before shipping, for extra protection.

“If you have time at home, which a lot of us have, you can make a difference with this in so many ways, whether it’s just spreading that flyer around, sewing the masks, 3D-printing the masks, or just talking about it. So many hospitals are willing to take what we offer, even if they just put it in storage, it makes them feel so much more comfortable doing their job when they know that they have something that they can protect themselves with.”

Throughout all parts of the world, many groups of people have gathered together to mass-produce masks and shields for those in need. Like Steele, they are determined to spread awareness and involve as many people as they can to help create a widespread sense of comfort during this pandemic. They hope that all this hard work will aid in returning normalcy to the world once again.

Contact Alliyah to help make a difference: [email protected]

![]() #HackThePandemic

#HackThePandemic